Hello, what comes to mind when you think of the packaging?

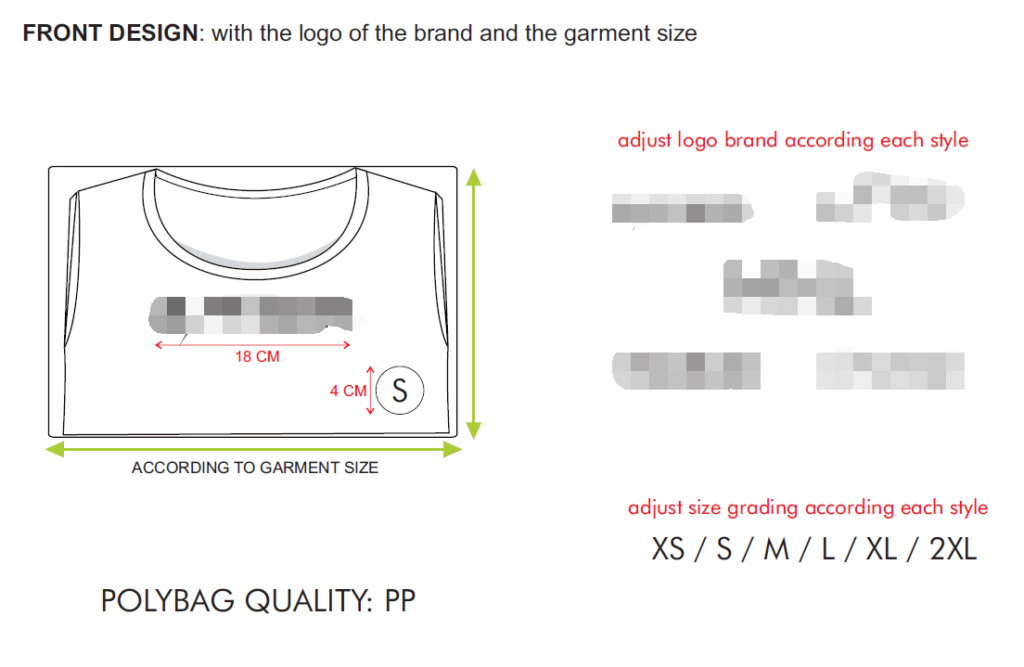

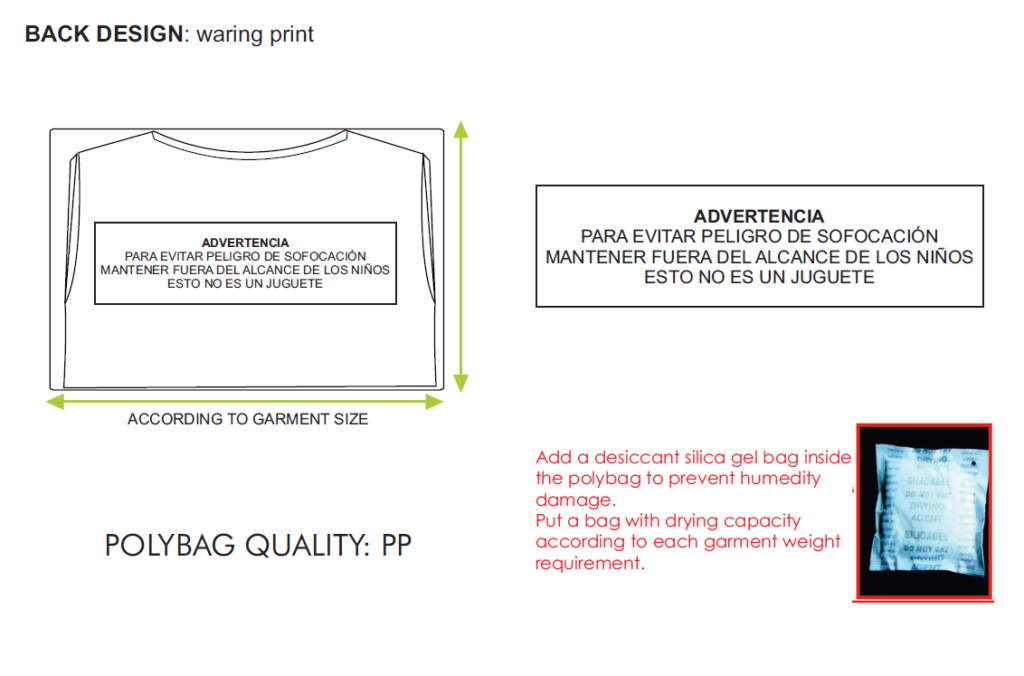

Here is an example of winter jackets. After the production is completed, it enters the packaging process. What materials need to be prepared? Let’s take a look at the overall packaging process first.

1. Tips:

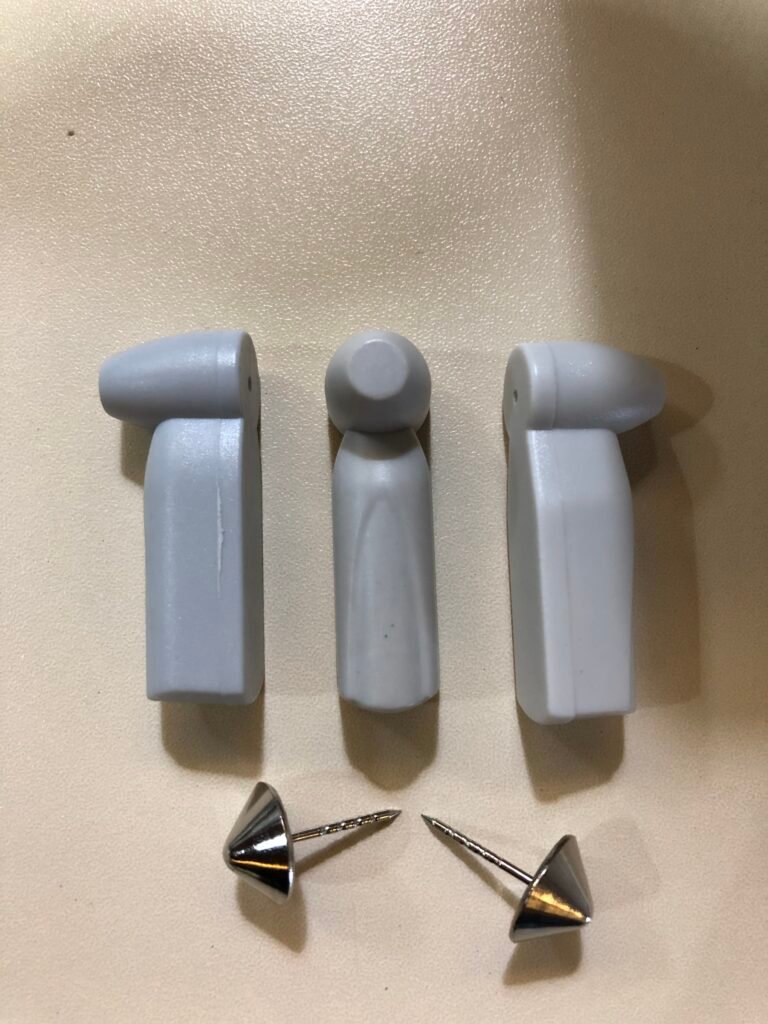

- Metal trims to be covered in tissue paper.

- When items are packed into cartons, all the garments must not be laid in the same direction. Swing each alternate garment in the opposite direction in order to have the garments stacked with the hem/ collar on top of each other. This assists with reducing impressions and movement inside the carton.

- Pay particular attention to folding the sleeves. If these are carelessly folded, the appearance of the garment will be affected and the garment heavily creased.

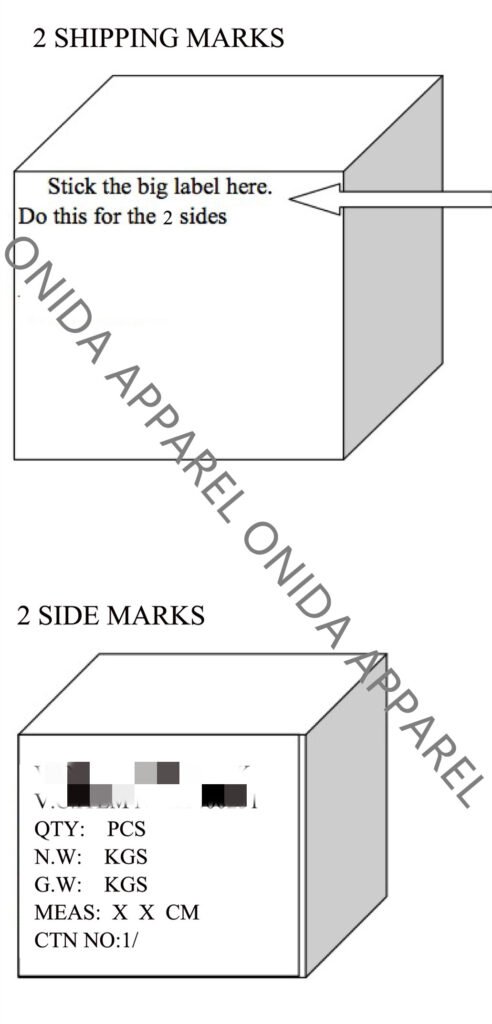

- Clarify your request on the out-of-ratio box and carton number.

- If the packing is complicated, send details once the order is placed.

2. Questions

Q1: How come my packaging request factory always fails to complete it?

A: 1. It’s really difficult to figure out.

2. The costs are higher than expected.

3. The factory is used to paying no attention or ignoring the packaging.

Q2: What if I want the size, color, and item number to be printed on the polybag or hangtag together?

A: It’s actually a math problem. As long as the factory had enough space, it would be possible to implement.

Q3:…

Is there a specific packing request you need to be met?

what questions do you have for us?